At ECMM, we are committed to delivering high-quality services that keep your turbomachinery running smoothly and efficiently. Contact us today to learn how we can support your operational needs with our expertise and dedication.

Inspection & Maintenance

- Open, Clean, and Inspect Turbomachinery: Our expert team meticulously opens, cleans, and inspects your turbomachinery to ensure it operates at peak efficiency.

- Non-Destructive Testing (NDT): We utilize advanced NDT techniques to identify potential issues without causing damage, ensuring safety and reliability.

Precision Alignment & Instrumentation

- Internal Alignments: Proper internal alignments are critical for efficient operation and reliability. Our specialists ensure precise adjustments using wire alignment, laser tracking, and or ERAG methods.

- Shaft Alignments: We use cutting-edge technology to perform accurate shaft alignments, reducing wear and enhancing performance.

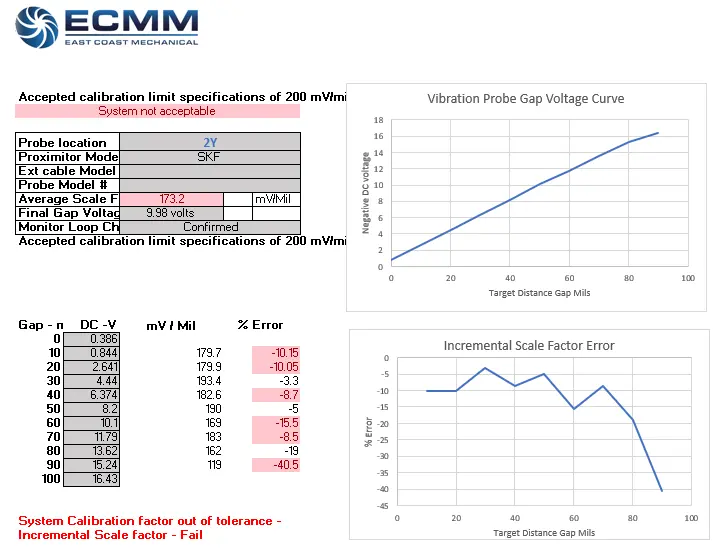

- Shaft Centerline Instrumentation Services: We provide calibrations and loop checks on eddy current vibration systems and temperature monitoring systems. View sample Cal Sheet.

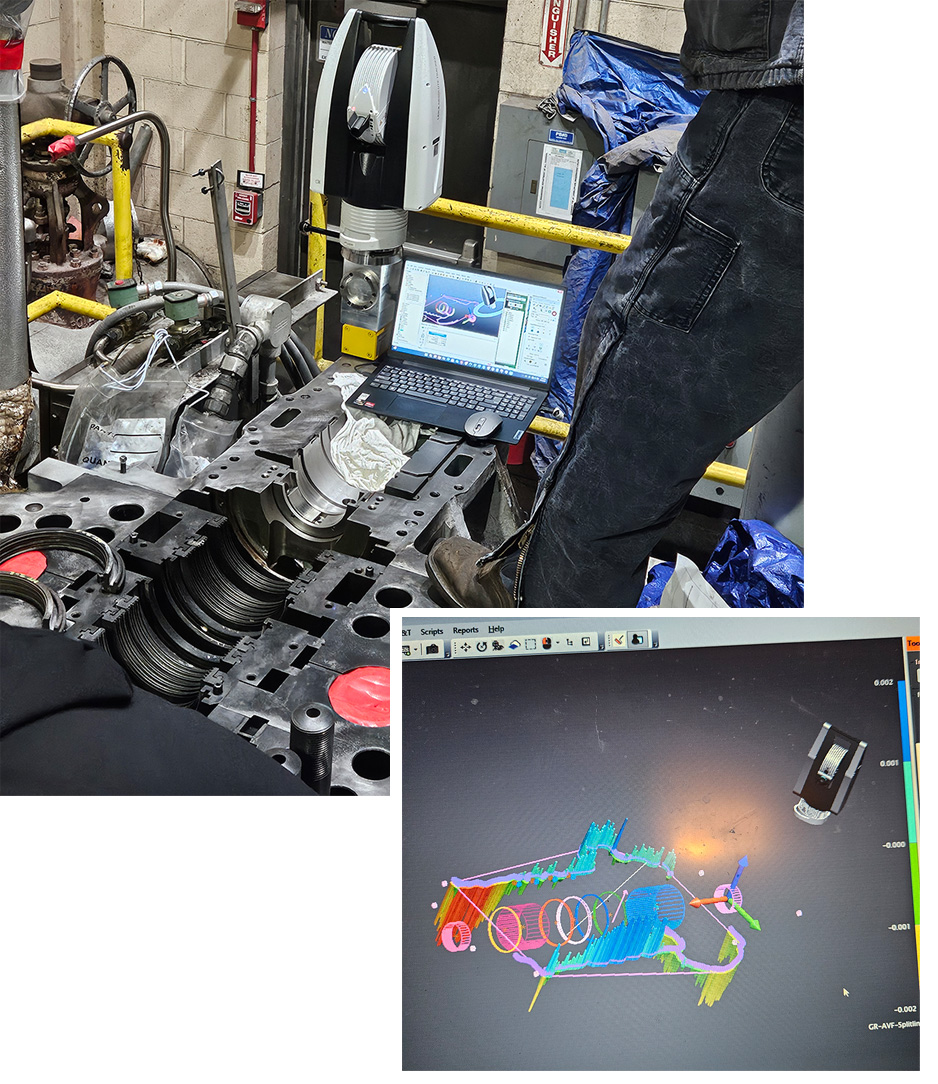

laser scanning and 3D modeling

- Our laser scanning and 3D modeling services provide precise, high-resolution digital replicas of machinery and components, ensuring accuracy in repairs, retrofits, and part fabrication. Using advanced scanning technology, we capture detailed measurements to create CAD models and engineering drawings, streamlining the repair process and reducing downtime. Whether for reverse engineering, component alignment, or structural analysis, our laser scanning solutions enhance efficiency and precision in machinery maintenance and restoration. In-house work with some preferred specialized sub-vendors when needed.

Project Management

- Project Management: From start to finish, we handle all aspects of your turbomachinery projects, ensuring efficiency and success.

- Technical Direction: Our industry experts provide guidance and oversight to optimize your turbomachinery operations.

- Turnkey Outages: We offer complete outage solutions, from planning and execution to final inspection, minimizing downtime and maximizing performance.

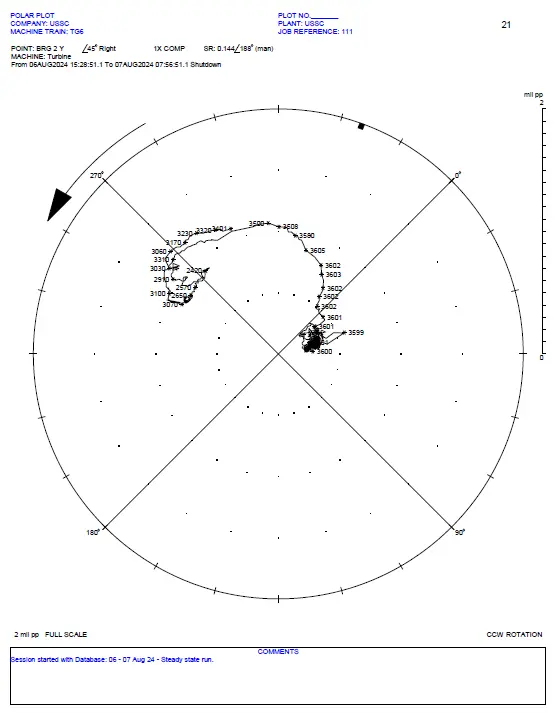

- Vibration Data Acquisition & Analysis and Field Balancing: We do in-house with some preferred specialized sub-vendors when needed. View Vibration Data Images

Specialized Engineering & Support Services

- Millwright Services: Our skilled millwrights handle installation, maintenance, and repair with precision and expertise.

- Metrology Services: We employ state-of-the-art metrology techniques to ensure accurate measurements and optimal equipment alignment.

- Subcontract Generator Electrical Inspections: We collaborate with trusted partners to provide thorough electrical inspections of generators, ensuring compliance and reliability.